Production line monitoring solution for industrial automation and smart manufacturing of the future

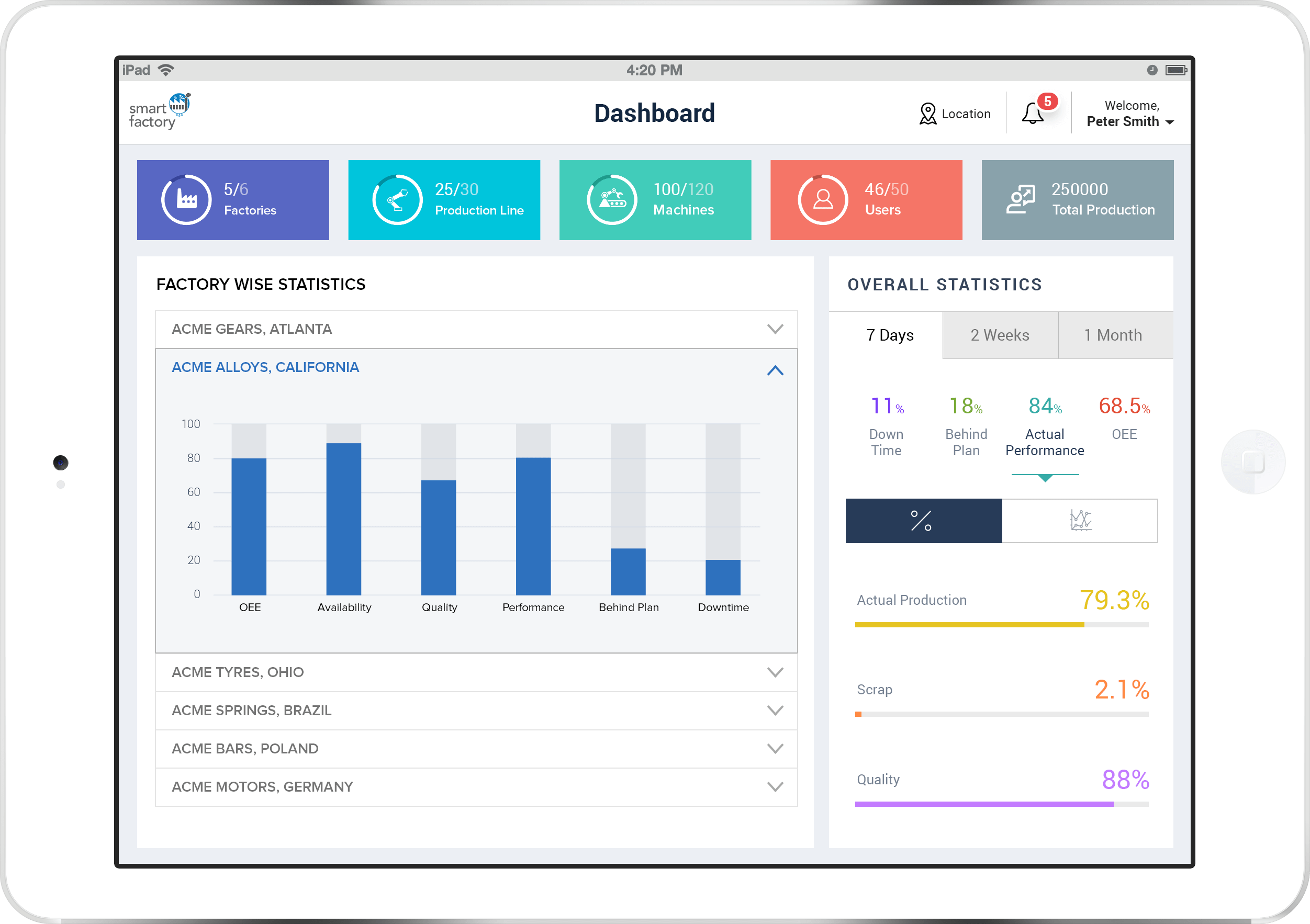

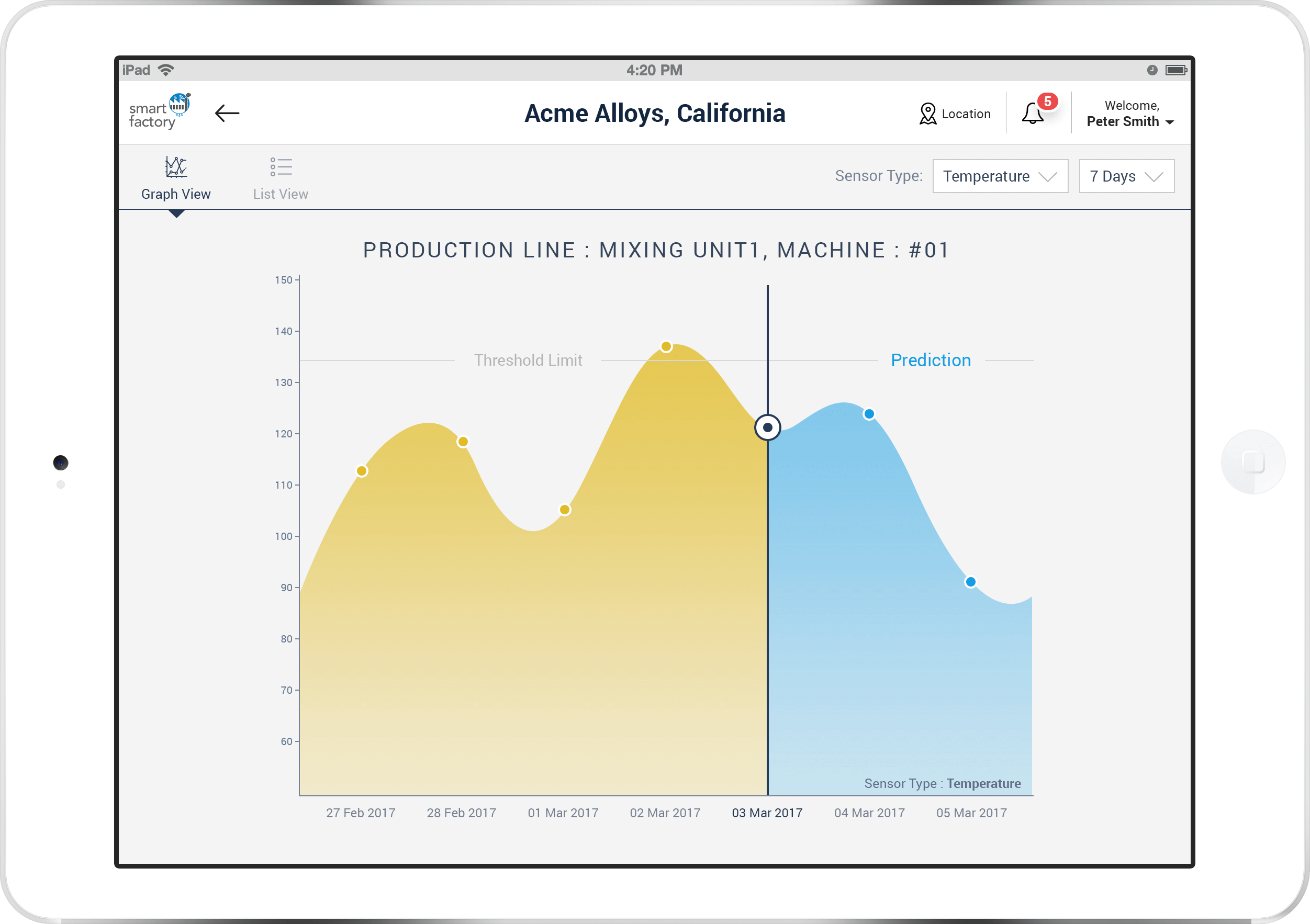

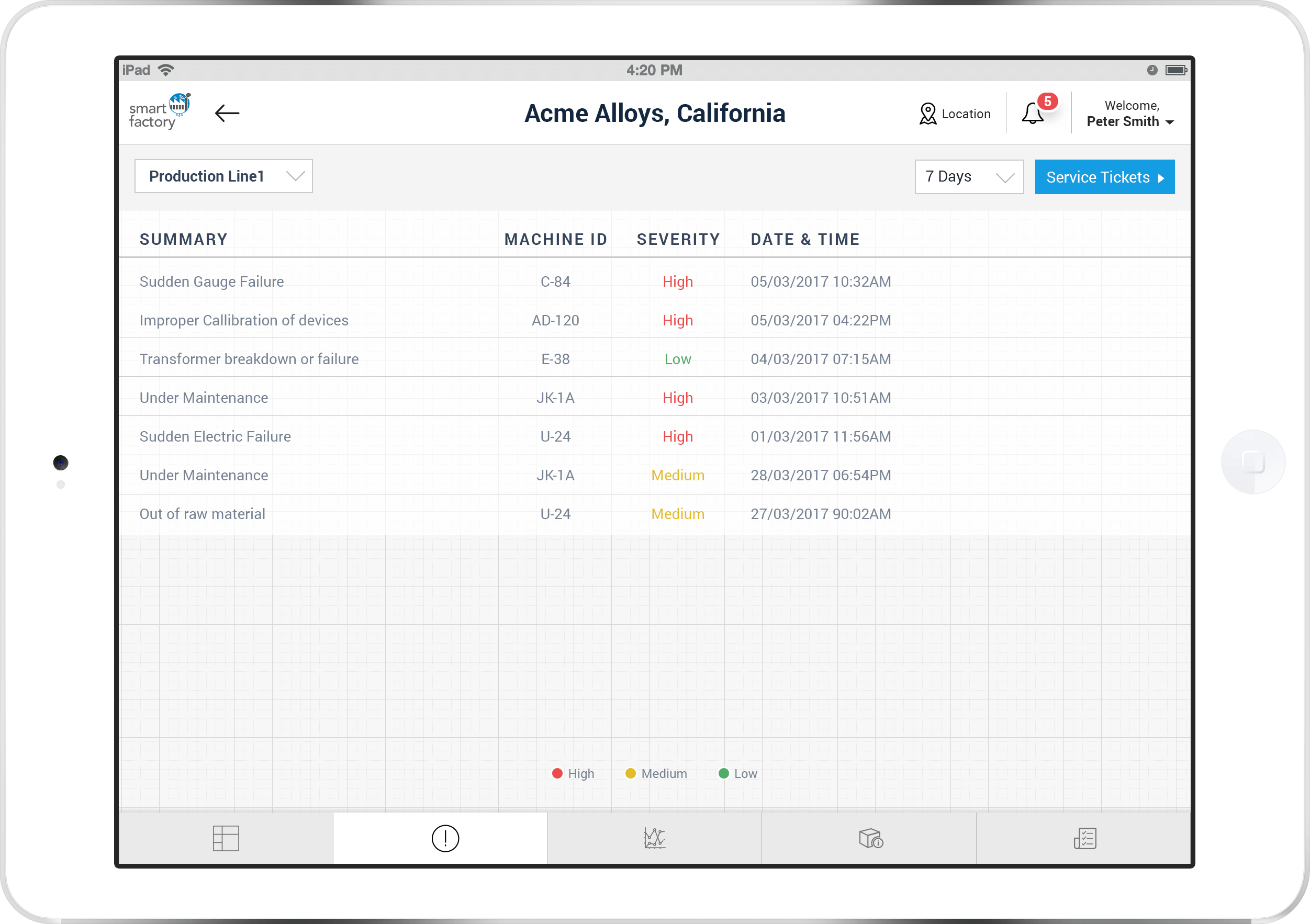

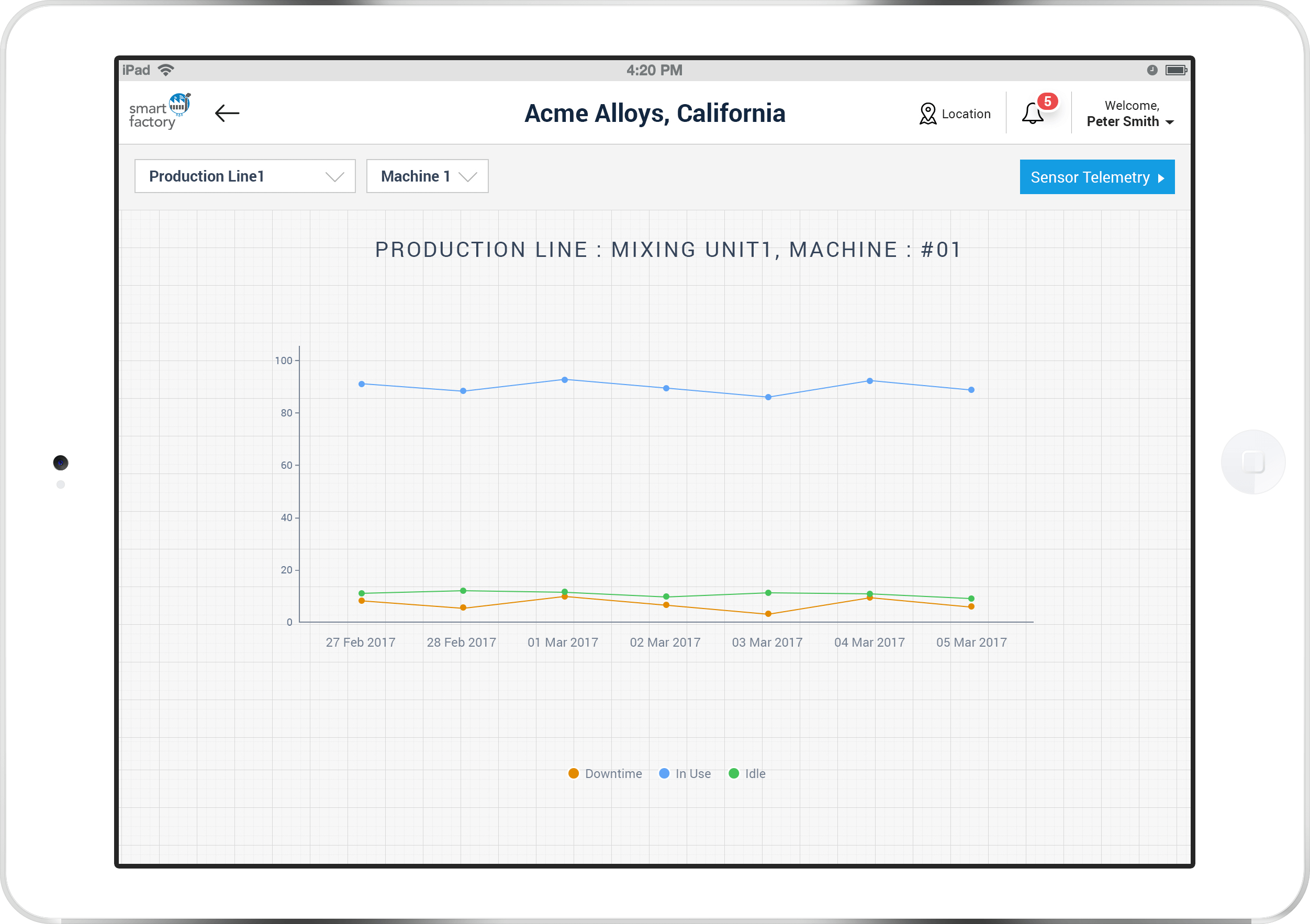

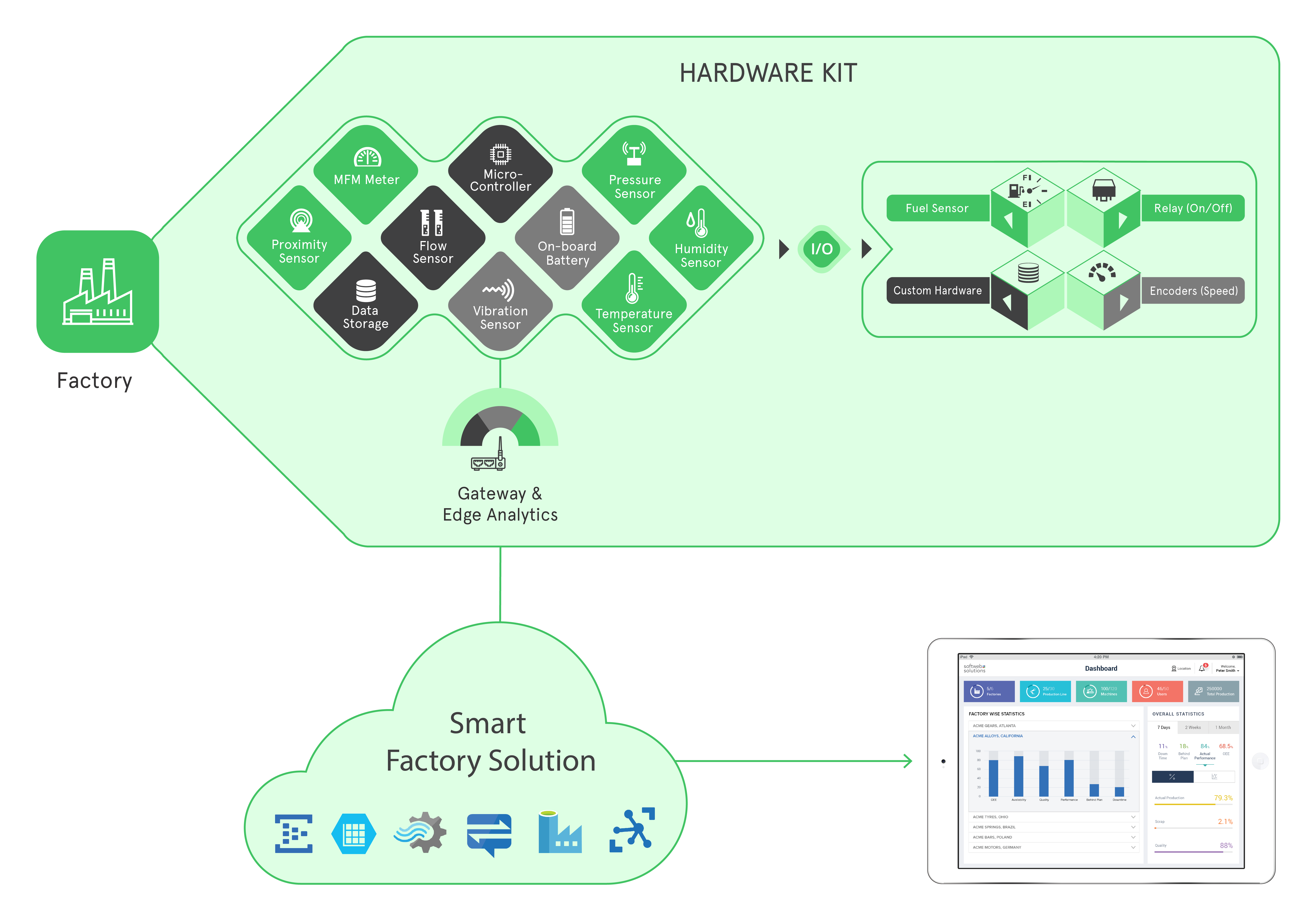

Avnet’s Smart Factory is a smart production line monitoring solution powered by AI and IoT technologies, which enables you to monitor everything on the shop floor from a centralized, live dashboard. Our industrial automation solution involves highly trained machine learning algorithms that can predict machine failures and brings higher operational intelligence that your legacy system was not able to perform.

Our Industry 4.0 solution enables manufacturers to connect multiple production lines and machines, acquire data at different stages of production from several disparate sources and develop capabilities like remote monitoring, edge analytics and predictive maintenance and digital twin.

Features

Our Smart Factory Solution has the capability to connect multiple sensors to monitor the status, automate, collect data, analyze it and derive useful insights to improve manufacturing operations.

Monitor the metrics that matter the most

-

OEE

-

Availability

-

Performance

-

Quality

-

Behind time

-

Downtime

Are you ready to take your first step towards Industry 4.0?

Get in Touch

Steps to implement Avnet’s Smart Factory Solution

Site assessment

Data point analysis and hardware kit finalization

Onboarding

Value realization

FAQs

Most Commonly Asked Questions Regarding Avnet's Smart Factory Solution

It depends on the readiness of your infrastructure and the business use case. However, if you are already collecting and storing data in any way, it would not take much time for set up and installation. In case you have any specific customization requirements for dashboard and reports, then it may affect the timeline.

Yes! We just need to assess your infrastructure and identify data points so that our technical team can guide you further. We will then integrate your current machines and help you make sense of your data.

During the assessment, our technical team will identify machines which are smart, semi-smart and dumb. Smart machines can be connected directly to the cloud. Semi-smart machines can provide a few data points directly to cloud and require external sensors/actuators in order to send any other data points. Dumb devices cannot provide any data and require external sensors/actuators to connect and send particular data to the cloud.

Yes. Our engineers will conduct an assessment of your facility to get a full understanding of the infrastructure and identify a solution on how to make your machines or assets IoT-enabled. In case of totally dumb devices, we can always set up an internet connection using external sensors and actuators.

Yes, Avnet’s Smart Factory can be implemented with the existing third-party cloud service provider. In this scenario, the solution will collect the data from the third-party cloud storage you are using and connect it to the IoT cloud. The solution will then use the data from the IoT cloud only.

The security of your data is paramount to us. All communication is secured with SSL and TLS protocols to ensure secured device management and connectivity management. Avnet’s Smart Factory Solution uses OAuth2 authentication which enables third-party applications to access the user accounts on an HTTP service.

It depends upon the use case. To discuss further, please write to us at info@softwebsolutions.com

Yes. The solution allows users to add multiple factories situated at different locations. Each factory can be divided into particular floors, production lines and stages/processes. Users can always view the generic dashboard along with the combined KPI values or the individual KPI values for each factory. The dashboard and reports can be customized as per your requirements.