The client is a leading manufacturing company specializing in industrial equipment production. With multiple production facilities across North America, the company operates in high-risk environments where worker safety is a top priority.

The company faced difficulties managing and analyzing large volumes of safety equipment data, leading to information overload. Real-time response to critical alerts remained an issue, especially for remote or large-scale operations. Moreover, integration into existing enterprise systems required additional technical effort, while connectivity issues had an influence upon GPS tracking and real-time notices. In addition, user adoption was a hurdle because the safety teams required training to fully utilize the features of the safety portal.

The company's aim is to contribute to environmental causes like reducing plastic waste. They also want to reduce packaging without sacrificing quality. Their customers also require adhering to such terms and supporting their cause. Hence, it was important for their clients to also have a 360-degree view of their machines and products. Some of the key challenges that obstructed the company from achieving the desired results were:

Key challenges:

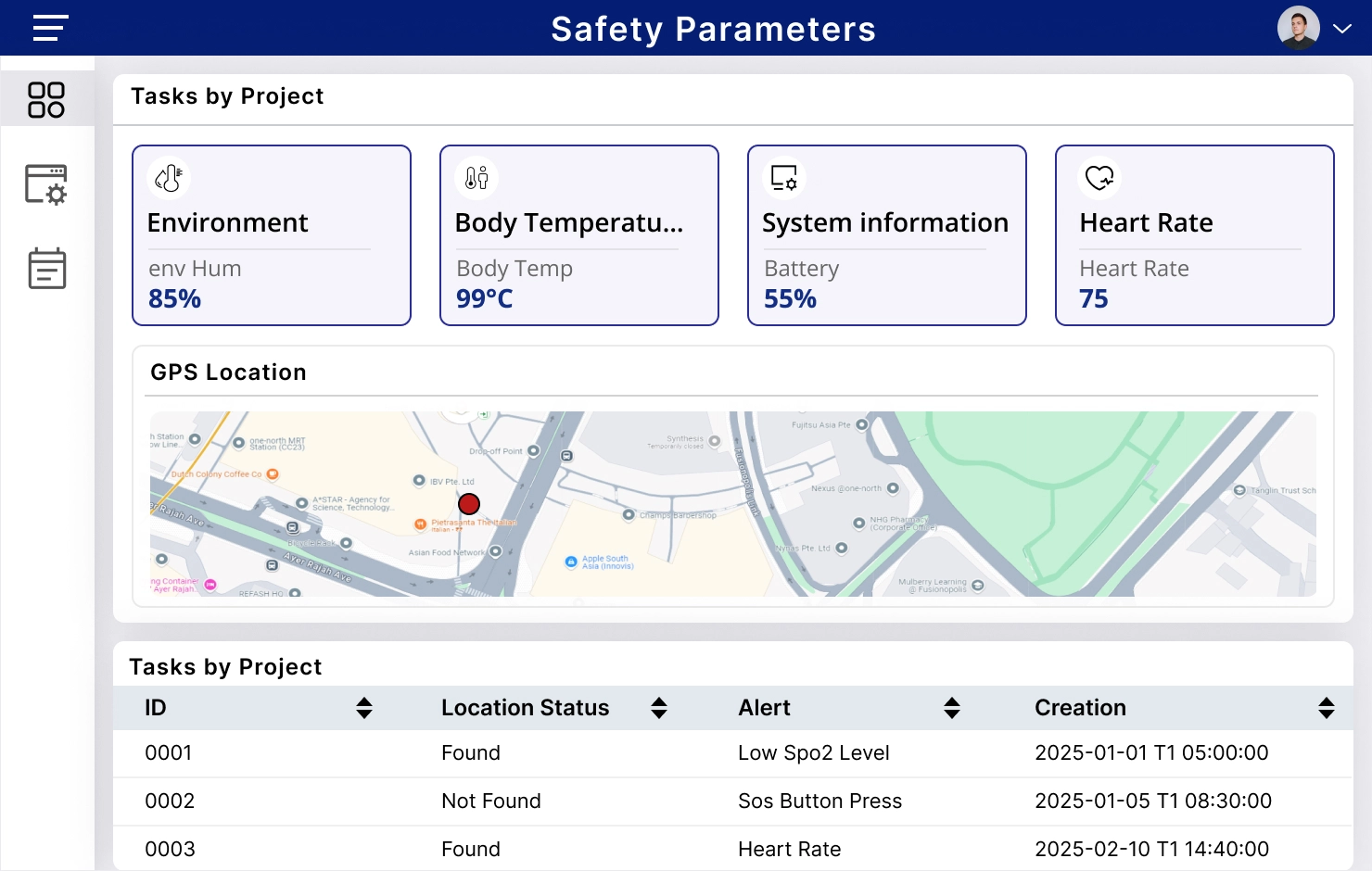

After assessing the company’s existing safety infrastructure, our certified AWS consultants provided a strategic roadmap to enhance safety monitoring and optimize workforce protection. Our recommendations focused on improving data management, real-time alerting, system integration, and overall user engagement. To address these challenges, we implemented advanced data visualization and filtering tools along with our IoT platform, /IOTCONNECT™, to simplify safety data analysis. We also introduced an automated alert prioritization to categorize alerts based on severity, ensuring quick response to critical incidents.

Manufacturing

Node.js , Express.js, Angular, React, /IOTCONNECT™, Amazon EC2, DynamoDB, Amazon SQS, MySQL

Projects

Technocrats

Products and Solutions

Customers